This product line is manufactured by MicrotracBEL-Japan, specialist in adsorption. MicrotracBEL, RETSCH Technology and Microtrac bring together a wide expertise in particle characterization under a strong brand name: Microtrac MRB GmbH.

SURFACE AREA AND PORE SIZE DISTRIBUTION ANALYZER

Physisorption products belong to a group of gas and/or vapor adsorption analyzers which brings together a full range of instruments covering surface area and pore size distribution analysis aimed to characterization of powder and porous materials in a wide spectrum of applications.

Physisorption products belong to a group of gas and/or vapor adsorption analyzers which brings together a full range of instruments covering surface area and pore size distribution analysis aimed to characterization of powder and porous materials in a wide spectrum of applications.

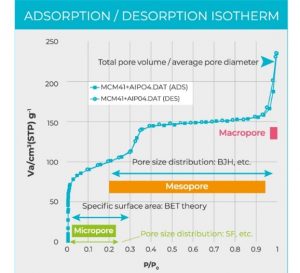

Physisorption devices determine surface area and pore size distribution from directly measured adsorption isotherm using volumetric gas adsorption. During determination of adsorption isotherms, the adsorption amount of a sample measured under constant temperature is then expressed as function of relative pressure, as shown in the figure.

Another way to measure the specific surface area (BET -single-multi point) is by means of dynamic gas flow method. In this method, the change of gas concentration after passing through the sample is detected by a thermal conductivity detector (TCD) and from the concentration change the adsorption amount is obtained thereafter surface area is calculated.

Physisorption portfolio contains the following devices:

SURFACE AREA AND PORE SIZE DISTRIBUTION ANALYZER

BELSORP MINI X

It is a compact and high precision volumetric physisorption device for specific surface area and pore size distribution analysis. It automatically measures adsorption isotherms according to minimum condition settings. It analyses up to 4 samples simultaneously and independently making use of Advanced Free Space Measurement (AFSMTM) technique. AFSM compensates for dead volume change in the sample tube to achieve high measurement precision and reproducibility.

It is a compact and high precision volumetric physisorption device for specific surface area and pore size distribution analysis. It automatically measures adsorption isotherms according to minimum condition settings. It analyses up to 4 samples simultaneously and independently making use of Advanced Free Space Measurement (AFSMTM) technique. AFSM compensates for dead volume change in the sample tube to achieve high measurement precision and reproducibility.

Simplified specifications

Specific surface area: 0.01 m2/g or above

Pore size distribution: 0.7 to 400 nm

PRODUCT ADVANTAGES

- Customizable with respect to the number of measurement ports: 3 or 4

- Dedicated exhaust valve and intuitive software

- Gas dosing optimization (GDO) based on adsorption isotherm data from previous sample measurements to reduce measurement time

- AFSMTM for increased measurement precision and reproducibility (Domestic patent: #3756919 / US Patent: 6,595,036)

- Gas Adsorption measurement of up to 5 gases over a wide range of temperatures

- Step-by-step software guide for replacement of gas cylinder, purging of the manifold and execution of measurements

- Service tool “System Check” for status control of inner components

- Simple mode is available for easy operation

SURFACE AREA AND PORE SIZE DISTRIBUTION ANALYZER

BELSORP MAX G

BELSORP MAX G is a volumetric physisorption device for determination of pore size distribution specific surface area, suitable for low surface area measurement using Kr and micropore analysis. BELSORP MAX G makes possible the physical characterization of zeolites, hybrid porous solid like metal-organic framework materials (MOFs), covalent organic frameworks (COFs) and many other porous materials.

BELSORP MAX G is a volumetric physisorption device for determination of pore size distribution specific surface area, suitable for low surface area measurement using Kr and micropore analysis. BELSORP MAX G makes possible the physical characterization of zeolites, hybrid porous solid like metal-organic framework materials (MOFs), covalent organic frameworks (COFs) and many other porous materials.

Simplified Specifications:

Specific surface area: 0.0005 m2/g

Pore size distribution (Diameter): 0.35~500nm

PRODUCT ADVANTAGES

- Affordable physisorption device

- Measurement in one sample cell and dead volume control on reference cell

- Gas dosing optimization (GDO) function for optimum gas dosing which decreases analysis time

- Flexibility: customizable pressure sensors and in-situ sample pre-treatment

- High precision measurement by Advanced Free Space Measurement (AFSMTM) and/or High precision measurement by Advanced Free Space Measurement (AFSM 2TM) . AFSM is extremely important for determination of low surface area

- Step-by-step software guide for replacement of gas cylinder, purging of the manifold and execution of measurements

- Service tool “System Check” for status control of inner components

- Simple mode is available for easy operation

- Analysis software includes GCMC and NLDFT simulations tool for both micro and mesopore analysis

SURFACE AREA, PORE SIZE DISTRIBUTION and MUCH MORE

BELSORP MAX II

BELSORP MAX II is a volumetric physisorption device for determination of pore size distribution specific surface area, suitable for low surface area measurement using Kr, micropore analysis, vapor adsorption measurements and adsorption rate well.

BELSORP MAX II is a volumetric physisorption device for determination of pore size distribution specific surface area, suitable for low surface area measurement using Kr, micropore analysis, vapor adsorption measurements and adsorption rate well.

Volumetric physisorption technique is widely used to evaluate the pore size of porous materials. Microporous material gives Type I isotherm. And mesoporous material gives type IV isotherm. By analyzing the Type I isotherm in the low pressure range, micropore size distribution is calculated, and from the Type IV isotherm in the middle relative pressure range, the mesopore size distribution is determined.

Simplified Specifications

Specific surface area: 0.0005 m2/g

Pore size distribution (Diameter): 0.35~500nm

What is the value of a BELSORP MAX II device for a user?

Example 1: in micropore size distribution analysis it is crucial to measure accurate adsorption isotherms in the low pressure range. So how software-hardware combination of BELSORP MAX II accomplish this task?

One hand BELSORP MAX II uses pneumatic valves, they minimize leakages in the system. Additionally, pneumatic valves are extremely important in vapor adsorption applications due to their reduced gas permeation and gas re-emission performance preventing cross contamination and corrosion.

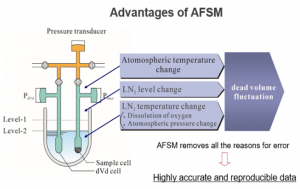

On the other hand, the Advanced Free Space Measurement (AFSMTM, US Patent:6.595.036) implemented also on BELSORP MAX II features an accurate method for determination of dead volume changes on the sample cell, thereby high precision determination of adsorption isotherms. The AFSMTM continuously measures the dead volume change caused by 1) the change of liquid coolant level; 2) the room temperature change during sorption measurement and 3) the temperature change of the refrigerant due to oxygen dissolution.

On the other hand, the Advanced Free Space Measurement (AFSMTM, US Patent:6.595.036) implemented also on BELSORP MAX II features an accurate method for determination of dead volume changes on the sample cell, thereby high precision determination of adsorption isotherms. The AFSMTM continuously measures the dead volume change caused by 1) the change of liquid coolant level; 2) the room temperature change during sorption measurement and 3) the temperature change of the refrigerant due to oxygen dissolution.

Example 2: In-situ features.

The qualitative estimation of pore structure of a material is possible only by using adsorption. Moreover, BELSORP MAX II can operate together with X-ray diffractometer to yield powerful equipment for ultimate in-situ powder characterization

Example 3: Uniqueness

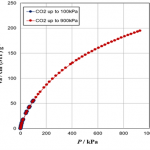

Device configuration with both high pressure and low pressure sensors on one device for example BELSORP MAX II HP with 13.3Pa, 1.33kPa, 133kPa sensors and one high pressure sensor in one port.

Device configuration with both high pressure and low pressure sensors on one device for example BELSORP MAX II HP with 13.3Pa, 1.33kPa, 133kPa sensors and one high pressure sensor in one port.

By measuring the adsorption isotherm of CO2 at 298K up to 900kPa, high reproducibility evaluation of specific surface area and pore size distributions of ultra-micropores to mesopores of 0.3nm to 10nm on activated carbon for LiB capacitor can be possible. Another example of high pressure adsorption is NH3 or H2 adsorption at 298 K which makes possible the evaluation of heat-pump performance and energy-storage by PCT curve.

BELSORP MAX II characterizes zeolites, hybrid porous solid like metal-organic framework materials (MOFs), covalent organic frameworks (COFs), carbon back, CNF and many other porous materials.

PRODUCT ADVANTAGES

- Highest throughput thanks to simultaneous measurement of up to 4 samples

- Gas dosing optimization (GDO) function to decrease measuring time

- Offers direct evacuation system and intelligent valve control to reduce measurement time

- Customizable: with respect to pressure sensors used

- Uniqueness: special system which offers operation with both high and low pressure sensors in one device.

- Ultra-micropore evaluation

- Flexibility: it allows in-situ sample pre-treatment

- High precision vapor adsorption measurement under strict temperature control

- High precision measurement by Advanced Free Space Measurement (AFSMTM) crucial for low surface area determination

- High quality components: Pneumatic valves

- Step-by-step software guide for replacement of gas cylinder, purging of the manifold, degassing of liquid adsorptive and execution of measurements

- Service tool “System Check” for status control of inner components

- Simple mode is available for easy operation

- Analysis software also includes GCMC and NLDF simulations tools for both micro and mesopore analysis

- Many options available

SURFACE AREA ANALYZER

BELSORP MR1

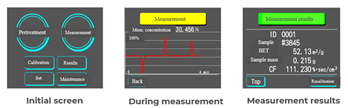

BELSORP MR1 is a semi-automated physisorption device for evaluation of BET specific surface area using dynamic gas flow method, fast and reliable.

Surface area: 0.01 m2/g and above

PRODUCT ADVANTAGES

-

- Suitable for QC

- Short Measurement time, about 20min including Calibration

- AUTO-ZERO function is equipped with a highly sensitive thermal conductivity detector (TCD).

- High accuracy, high sensitivity, high reproducibility.

- Calibration valve for simple and stable calibration

- Automatic measurement of temperature and pressure for accurate calibration

- User-friendly touch panel

- Simultaneous pre-treatment and measurement improve process efficiency

- It does not need vacuum pump

AUXILIARY DEVICE FOR PHYSISORPTION ANALYZERS

BELPREP VAC

It is a sample degassing station for physisorption devices BELSORP MINI X, BELSORP MAX G, and BELSORP MAX II. BELPREP VAC degasses and heat treat samples up to 450⁰ C in vacuum. Two types are available:

BELPREP VAC II, 3 ports

BELPREP VAC III, 6 ports