The best dispersion results are obtained when the geometry of the dispersion container, the diameter, the peripheral velocity and the height of the dissolver disc above the bottom of the vessel as well as rheological millbase properties are matched to one another.

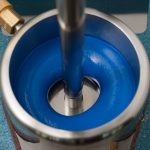

After adding pigments and fillers to resin solution, the millbase is brought into a laminar rolling flow pattern by increasing the speed of the shaft until no standing material can be seen at the wall of the container. At the correct speed, a channel begins to form around the shaft and a part of the dissolver disc becomes visible. At this point, the millbase will form a doughnut-like flow pattern. The doughnut-like pattern flow pattern is a signal that the maximum mechanical power possible is being transferred into the millbase.

Innovative dispersion and fine grinding systems for laboratory and pilot plant: VMA-GETZMAN offers a whole range of innovative systems for dispersion and fine grinding. From laboratory to pilot plants. Meeting all your needs as for example explosion proof, high viscosity and vacuum conditions. All with VMA:s well reputed technology, functional design as well as the high quality.

Product link: http://www.vma-getzmann.com/english/home/home_0_935_2317.html